Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Hello There! Ever wondered… Does Aluminum Rust? today we’ll uncover the secrets of aluminum corrosion, its unique protective mechanisms, and how you can shield it from the clutches of corrosion.

Get ready to explore, learn, and ensure your aluminum creations stand the test of time!

Before we get into the nitty-gritty of aluminum corrosion, let’s set the record straight: Aluminum doesn’t rust like iron.

Rust is that reddish-brown stuff you see on iron and steel when they react with oxygen and water.

Aluminum, being a different kind of metal, has its own way of dealing with corrosion.

Think of corrosion as a natural process where metals gradually break down due to chemical reactions with their environment.

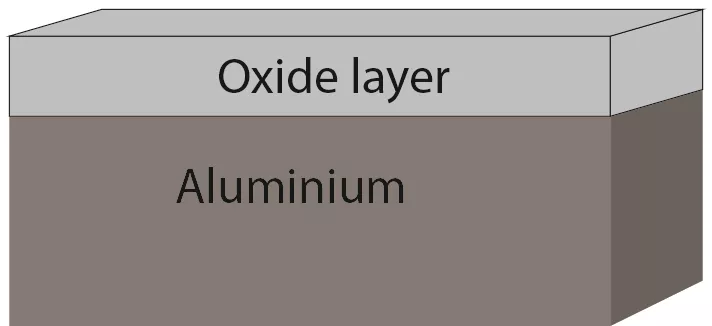

But fear not, because aluminum comes prepared! It forms a super-thin oxide layer when exposed to air, creating a protective shield that keeps the metal beneath safe and sound.

Ahoy, sailors! When it comes to saltwater, aluminum is a formidable contender against corrosion, but it’s not invincible.

Pitting corrosion is the name of the game in marine environments – small pits form on the surface due to chemical reactions.

So, while aluminum is a brave sea warrior, it can still use some backup against the salty onslaught.

Corrosion isn’t a one-size-fits-all deal. Here are some factors that can corrode you aluminum:

Environmental conditions, pH levels, temperature changes, impurities in the alloy, surface defects, and even mechanical stress can all play a role in how aluminum fares against corrosion.

Even mechanical stress can all play a role in how aluminum fares against corrosion.

It’s like a complex dance where multiple factors influence the outcome.

Preventing aluminum corrosion is like maintaining a suit of armor. Regular cleaning and maintenance are your trusty allies in this battle.

Add protective coatings to the mix, and you’ve got a winning strategy.

These coatings act as shields, standing between aluminum and the elements, extending its lifespan.

We have a video for you by HomeBuiltHELP that explains how to use ACF-50 or CorrosionX to prevent aluminum, we’ll also leave detailed written instructions below:

Products like ACF-50 and CorrosionX are designed to provide protection against corrosion for metals including aluminum.

Using corrosion inhibitors like ACF-50 and CorrosionX can significantly extend the lifespan of aluminum components and structures, especially in environments prone to causing corrosion.

Regular maintenance and periodic inspections are crucial to ensuring continued protection.

There are many ways and steps and practices to prevent aluminum oxidation, Let’s break it down into actionable steps:

You can also watch this video that explains how to prevent aluminum corrosion:

Maintaining aluminum’s corrosion resistance is like nurturing a plant:

1.- Clean Gently: Wipe away dirt and pollutants to keep the oxide layer in top shape.

Use a soft cloth or sponge, and avoid abrasive materials that could scratch the surface.

2.- Apply Protective Coating: Think of it as sunscreen for your metal – a protective coating keeps the oxide layer intact.

There are various coating options, including paint, epoxy, and powder coating. You can also use corrosion inhibitors.

Consult with professionals to determine the best fit for your specific needs.

We also added a video on a popular aluminum protection below uses a popular aluminum corrosion inhibitor called CRC 3-36, very nice choice if you want to protect your aluminum from corrosion

3.- Monitor and Act: Regularly check for changes and be ready to address any issues promptly.

Here’s another video on how to prevent aluminum from corrosion:

If you notice signs of corrosion, such as discoloration, rough spots, or pitting, take action immediately to prevent further damage.

Now, let’s delve into a thrilling comparison between aluminum and its arch-rival, steel. Imagine this showdown as a clash of titans, each armed with its own unique set of abilities in the battle against corrosion.

Picture aluminum as a valiant knight, clad in a gleaming armor of self-preservation. Its secret weapon? The remarkable oxide layer that forms on its surface.

This super-thin barrier acts as an impenetrable shield against the elements, thwarting the advances of corrosive agents.

Whether it’s rain, humidity, or even airborne pollutants, aluminum’s oxide layer stands strong, providing formidable corrosion resistance.

Now, let’s turn our attention to steel, the timeless contender in the realm of metals.

Steel, though robust and versatile, faces a relentless adversary in the form of rust.

When iron in steel reacts with oxygen and water, it undergoes a chemical transformation that results in rust – a brittle and damaging compound that weakens the metal’s structural integrity.

Unlike aluminum’s innate ability to form a protective oxide layer, steel requires external measures to combat corrosion effectively.

Coatings such as paint, galvanization, and specialized rust-resistant treatments are the armor that steel dons to fend off rust’s advances.

These coatings act as a barrier, preventing direct contact between the steel and corrosive agents. While effective, they require consistent maintenance and periodic reapplication to uphold their protective capabilities.

Let’s sum up the battle between aluminum and steel in a head-to-head comparison:

| Characteristic | Aluminum | Steel |

| Natural Protection | Self-forming oxide layer | Requires external coatings |

| Vulnerability to Rust | Very Low | High |

| Maintenance | Minimal | Regular upkeep required |

| Longevity | Enhanced durability | Prone to degradation over time |

| Environmental Impact | Recyclable and eco-friendly | Requires energy-intensive production |

In this clash of corrosion resistance, aluminum emerges as the undisputed champion.

Its inherent ability to form a protective oxide layer grants it a substantial advantage, reducing the need for constant maintenance and ensuring longevity.

On the other hand, steel’s battle against rust demands vigilant care and external interventions to maintain its structural integrity.

While both aluminum and steel have their merits, but both of them rust or corrode. The decision of which metal to use ultimately depends on the specific application.

If corrosion resistance is a top priority, especially in environments with high humidity or exposure to corrosive substances, aluminum proves to be the superior choice.

Its ability to maintain its structural integrity over time with minimal intervention makes it an excellent option for outdoor structures, marine equipment, and various industrial applications.

In contrast, steel’s strength and affordability make it a preferred choice in applications where corrosion resistance is less critical.

With proper coatings and maintenance, steel can still serve admirably in construction, automotive manufacturing, and other sectors.

Aluminum takes the crown with its self-sacrificing oxide layer!

Powder coating is like armor with a stylish twist. It involves applying dry powder to aluminum, which transforms into a protective layer upon heating.

It not only shields against corrosion but also adds a pop of color and style to your metal creations.

Here’s a video that explains what powder coating is:

Anodizing is like sending aluminum to a rejuvenating spa. It thickens the oxide layer, enhancing corrosion resistance and durability. It’s like upgrading your armor to the next level.

Nope, they’re not the same! Rust is specific to iron, while aluminum’s oxidation forms a protective layer that prevents further corrosion.

So, the next time someone mistakes your aluminum piece for being rusty, you can proudly educate them about its battle scars against corrosion.

Congratulations, you’ve now mastered the art of aluminum corrosion prevention!

By understanding aluminum’s unique properties, protective mechanisms, and implementing smart strategies, you can ensure your metal creations stay stunning and corrosion-free.

Remember, aluminum might not rust like iron, but it’s still essential to give it the care it deserves. Until next time, keep those metals shining and the corrosion at bay!

Aluminum does not rust like iron; instead, it forms a protective oxide layer that prevents further corrosion. To understand how aluminum’s resistance to rust compares to other metals, explore the following resources:

If you also want to learn more about some other less common metals, their uses, history, facts and much more here we have some other honorable mentions worth checking out:

By exploring these different metals and their resistance to rust, you can gain a comprehensive understanding of how aluminum’s properties compare with the unique characteristics of other essential materials.

Thank you so much for reading! Please stay tuned to further blog posts and other metal guides and information about Aluminum. You can also check our home page if you’d like to invest in or buy metals and other commodities.